This is a guest opinion post from Henry Ines, co-founder and CEO, Chainparency.

In late-August 2024, Michael Green Architects (MGA) unveiled the City of Milwaukee’s Marcus Performing Arts Center redevelopment plans, which include the building of, what is expected to be, the world’s tallest “mass timber” skyscraper (pictured). At 600 feet tall (55 stories), the 1.2 million square feet multi-tower complex development is expected to surpass the previously crowned “tallest” hybrid mass timber structure, Burj Zanzibar – a 28-story residential complex under development in Zanzibar and Africa’s first “wooden high-rise”.

Following MGA’s announcement, Woodlands, TX developer Howard Hughes announced that One Bridgeland Green, Houston’s first mass timber commercial building, was already 80 percent pre-leased after just three months of breaking ground in May 2024. The 49,000 sq feet “green” office building is being built with North American timber, will incorporate rooftop solar panels, and include a 10,000-gallon rainwater cistern.

The mass timber revolution

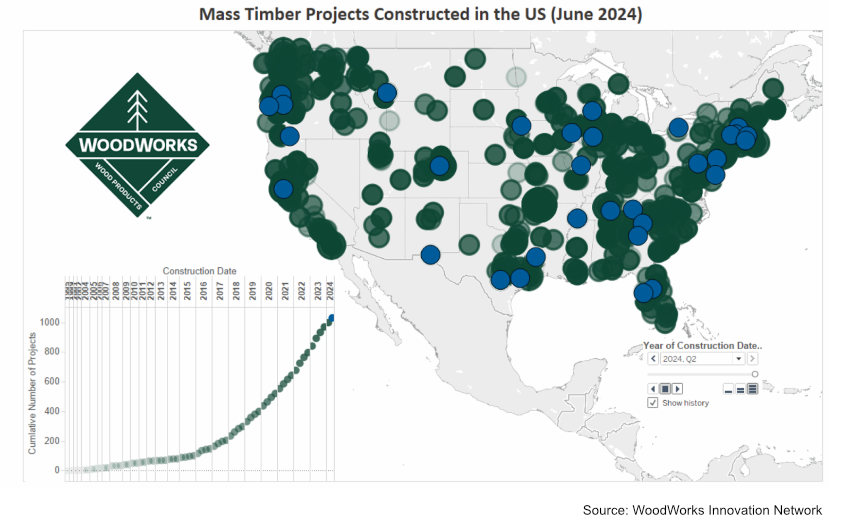

One Bridgeland Green, Burj Zanzjibar, and other projects including now third tallest mass timber building, Ascent, a 25-story hybrid mass timber building – also under development in Milwaukee – represent a growing global trend of real estate projects using engineered wood-based products instead of traditional concrete- and steel-based building materials. These projects are rapidly transforming residential and commercial landscapes around the world. According to non-profit Woodworks, there are more than 2,200 mass timber projects either in progress or completed as of June 2024 in the USA.

The Beck Group, Forest Business Network, Treesource, and Kaiser + Path predict the number of mass timber buildings in N. America could double every two years through 2034 at which point 12.9 billion board feet of lumber would be required to produce the estimated 24,000 mass timber buildings annually.

Why mass timber?

The American Wood Council defines mass timber buildings as “constructed with large pre-manufactured, multilayered, solid wood panels resulting in solid timber floors and walls typically ranging from 5 to 12 inches in thickness.” Rather than conventional materials, a mass timber building is constructed based on renewable and sustainably-sourced engineered and fabricated wood components like cross-laminated timber, glued-laminated timber, and nail-laminated timber products.

Select, high quality wood, is sourced, cut, and uniquely glued together in a way that forms structurally strong, versatile, and durable lego piece-like components, which are assembled to form large-scale wood-based beams, flooring, columns, panels, and other building components for mass timber developments.

With their environmental benefits and lower carbon footprint outcomes, the mass timber movement is countering the legacy construction industry, which currently contributes to almost 40% of total carbon emissions globally. On average, more than 40% of greenhouse gas (GhG) emissions can be avoided if engineered wood products are used in lieu of traditional concrete- and steel-based materials – which have a substantially larger carbon footprint and energy requirements. Sequestered carbon in wood is stored for decades. Then at the end of its product life cycle, mass timber buildings can be disassembled with wood components beneficially up-cycled and repurposed. Mass timber buildings are faster to construct, may be more fire resistant, offer insulation benefits and energy savings. Moreover, mass timber buildings may also result in health and well-being benefits due to the natural aesthetics and nature-based qualities of wood-based environments.

Deforestation & supply chain risks

The strong demand for mass timber projects is accompanied by growing concerns over deforestation, land conversion, and other potentially negative impacts to our forests. To determine the net environmental impact and benefits, the entire wood product lifecycle must be measurable and clearly understood. Supply chain transparency is essential to validate and ensure timber and lumber products are originating from sustainably-sourced and responsibly-managed working forests. As wood is consumed throughout the value chain, product inputs as well as any wood waste (destined for landfills) must be accounted for to better verify carbon footprint and GhG emissions. Opaque and highly fragmented supply chains, antiquated data collection & record keeping systems, and other legacy approaches, however, make it difficult to accurately measure, quantify, and validate end-to-end activities throughout wood product lifecycle and value chains.

Technology and data-driven solutions are key

Determining the net environmental benefits of mass timber projects will ultimately require the collection of high integrity data to prove product origination, measure lifecycle events, and validate product and project claims. The use of latest technologies, i.e. mobile devices, drones, satellite, and connected sensors, should be utilized to accurately and timely record key data events and activities throughout wood product value chains and to measure environmental impact from harvest to final point of delivery.

Digitizing supply chains is an important first step but data is corruptible, perishable, and subject to alteration. Blockchain technology ensures the integrity of the collected data, which is secured, time-stamped, irreversibly recorded, and 24/7 auditable. Blockchain can be used to record among other things key data like latitude and longitude coordinates of harvest sites, unique IDs, and GPS events related to the granular tracking and tracing of wood products and components. Blockchain-based approaches will also help to streamline the sharing and reporting of data.

Leading organizations and early adopters are already starting to utilize blockchain technology in forestry supply chains. For example, The U.S. Endowment for Forestry & Communities and its ForesTrust Network, a growing consortium of enterprises and organizations, are using blockchain technology in forestry supply chains to validate product claims, optimize supply chains and digitally streamline workflows, comply with global regulations, and to advance sustainability and climate-smart goals.

Mass timber projects, as part of a broader portfolio of net zero and GhG reduction initiatives, can help us achieve our climate and sustainability goals. However, the use of cutting-edge technologies like blockchain throughout forestry value chains are essential to better measure, monitor, report, validate, and ensure the mass timber developments and other sustainability initiatives are achieving the intended environmental, conservation, and carbon reduction outcomes for which we aspire.