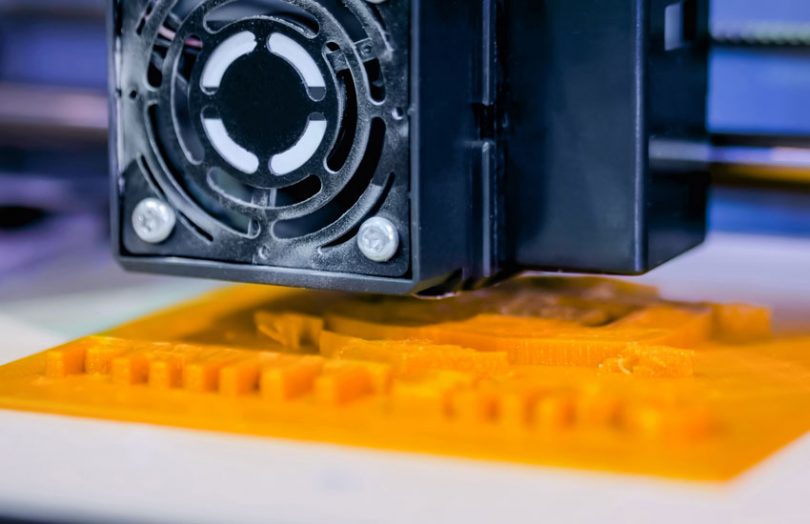

Yesterday, the European Commission-funded AMable initiative announced its fourth open call to grant €450,000 for SMEs in the Additive Manufacturing field, otherwise known as 3-D printing.

One of the Amable solutions is to help inventors to protect the rights to their designs using blockchain.

AMable aims to make new manufacturing technologies available to SMEs to enable them to create new products and generate new business models while saving them time and cost. The AMable platform is trying to provide smaller firms with unbiased access to knowledge of 3D printing processes.

When a new product is invented, it goes through multiple processes before it is manufactured. This includes design, adding functionality, improvements and making a prototype. In the course of this creative process, the iterations of the 3D designs may get lost, and there is no way to prove ownership of data. In essence, the AMable platform enables inventors to protect their rights in the data generated in the production of a product, particularly 3D designs.

To achieve this, AMable is relying on Industrial Data Space (IDS) and blockchain. AMable IDS is a network of different participants which supports secure exchange of data within the 3D printing sector. Using the IDS portal, a company can control which data is sent to whom.

Blockchain is being used to secure this exchange of data. AMable’s solution integrates with IDS to enable tamper-proof documentation of data sets. The platform generates a digital fingerprint of a file and connects it to the author’s identification. This fingerprint is stored on the blockchain with the author’s name, creating an immutable block or record of the dataset.

An owner of the data can prove his ownership by generating a new digital fingerprint and matching it with the one stored on the block.

The solution was developed by German research institute Fraunhofer ILT using Hyperledger Fabric.

This isn’t the first project to use blockchain for 3D printing. Several other initiatives also store a fingerprint of designs, but often the aim is to ensure the design is not tampered with. GE Research developed a project for this, and the U.S. Airforce is developing a similar solution with SIMBA Chain.

Last month Air New Zealand trialed a blockchain system from aircraft-parts maker Moog where a 3D-printed replacement part was installed on an aeroplane.