Yesterday industrial blockchain firm Data Gumbo announced a contract with Norway-based deep tech company Fieldmade. The Norwegian company delivers 3D designs so that its defense and energy clients can manufacture parts onsite. The project aims to leverage Data Gumbo’s blockchain network, GumboNet, to verify the origin of Fieldmade’s 3D product designs and materials. Houston-based Data Gumbo is backed by energy firms Saudi Aramco and Equinor.

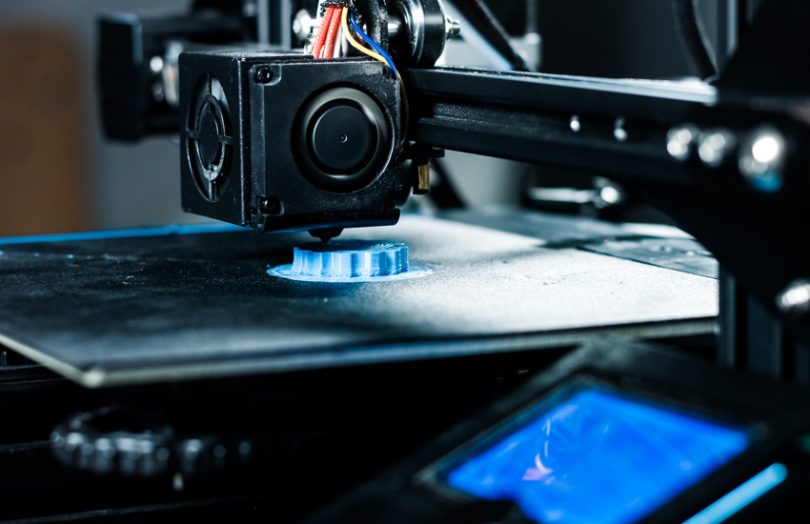

With 3D printing, or additive manufacturing, the importance of using the correct design or quality of metallic components for parts cannot be overstated.

Fieldmade CEO, Christian Dunn Norberg, hopes Data Gumbo’s network will increase the trust in all stages of their equipment supply market place. He also mentions GumboNet offers Fieldmade additional security to protect intellectual property and other sensitive information, ensuring transactional certainty.

Article continues …

Want the full story? Pro subscribers get complete articles, exclusive industry analysis, and early access to legislative updates that keep you ahead of the competition. Join the professionals who are choosing deeper insights over surface level news.