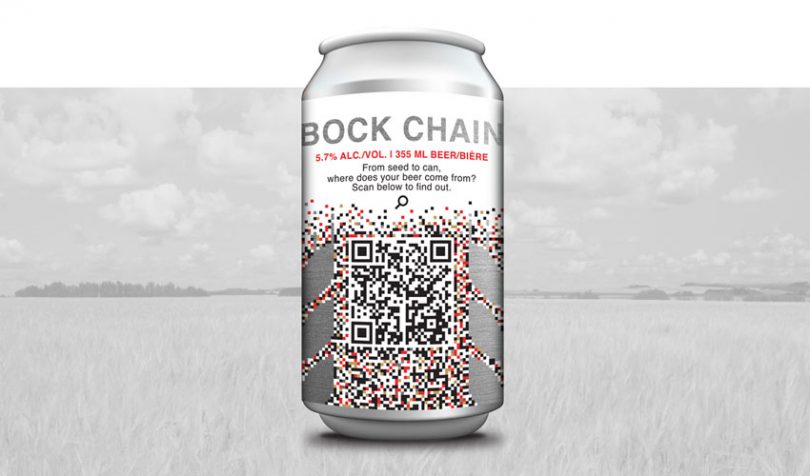

A group of Canadian companies has teamed up with TE-FOOD to produce a traceable beer called “Bock Chain” to be released tomorrow. The name may be gimmicky, but the companies clearly put quite a bit of effort into delivering rich content for this food traceability demonstration. German-based TE-FOOD is one of the most active startups in the sector with clients including French retailer Auchan and a major Vietnamese pig traceability project involving 6,000 companies.

The aim is to provide improved transparency to consumers who can see where the ingredients come from, how it’s processed, and all the steps from farm to table. Or in this case, field to can.

“It’s very rewarding to see the entire process, and to know what’s in this beer and that it came from my Dad’s farm,” said Matt Hamill, Owner of Red Shed Malting which performed the roasting.

First impressions after scanning the barcode (try it) was how polished it was. There was even a timelapse of the barley growing on the farm. It’s a great example of turning the traceability functionality into a marketing opportunity.

Give me more

But beyond the gloss, it raises some issues, not particularly for this project but for most food traceability projects. By offering some information, there will always be demands for more. Plus there’s a need for a standard summary presentation. And finally, consumers aren’t experts, so some data is less meaningful. That doesn’t mean data should be dropped, but it could be consumer-friendly.

In the Bock Chain beer example, Hamill Farms provided details about the variety of barley and the benefits of that variety. But where was it sourced? We concluded Canada after some googling. Which pesticides and herbicides were used and in what quantities? Not all suppliers will be comfortable about disclosing pesticide use. But that demand will increase.

There’s perhaps a need to have a standard format for displaying essential information so that busy people can skim it. The detail is excellent, but a summary is needed. That might involve a grid including seed source, farm, processing, logistics, etc. And each column would contain scores, for example, levels of pesticide use as high, medium, or low. Another example is whether refrigeration was satisfactory for certain types of foods.

SGS inspected the grain, and the full details of the inspection are available. Although the report was perfectly legible, consumers don’t have the skills to interpret it. There was no pass or fail or indication if any of the analysis is high or low. Hence there could be additional demands on inspection companies to produce consumer-style summaries that interpret the report.

Despite honing in on some areas that need consideration, the demonstration is nonetheless impressive.

Hanson Wade are running a conference called Blockchain for the Food & Beverage Supply Chain in San Francisco on March 26-27 2019. Ledger Insights is a media partner.

TE-FOOD tokens are not owned by the author or any Ledger Insights team members.